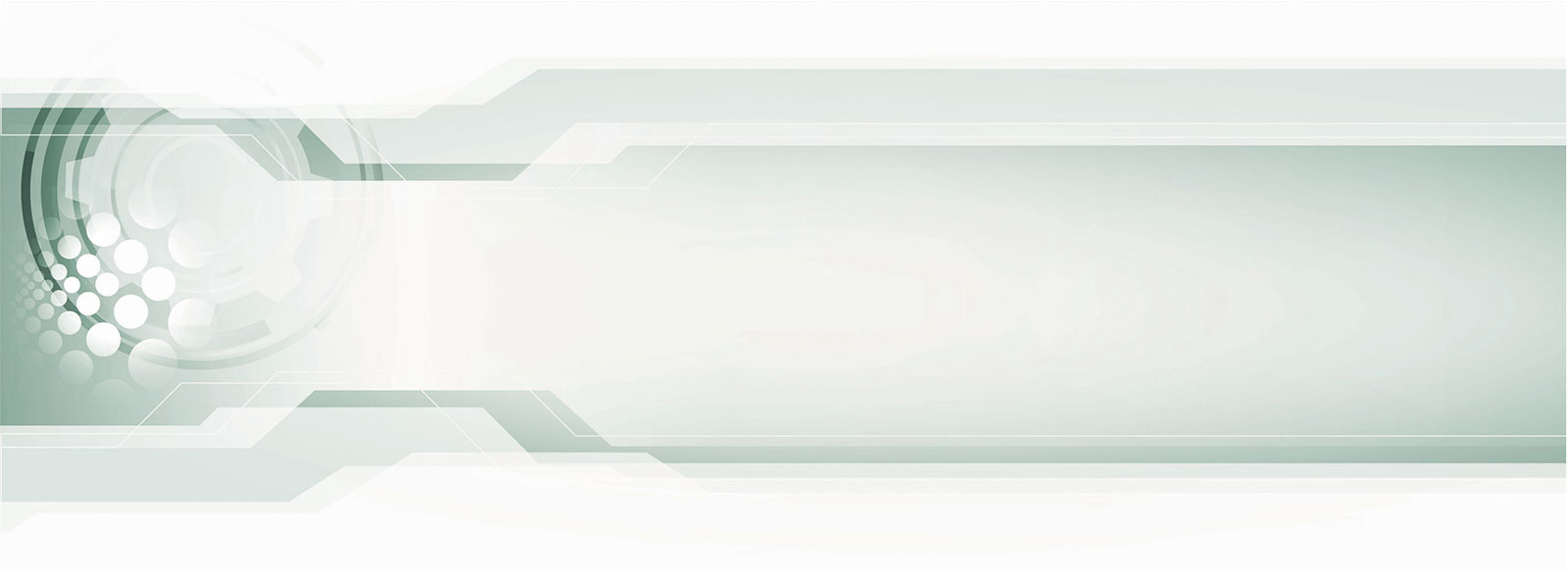

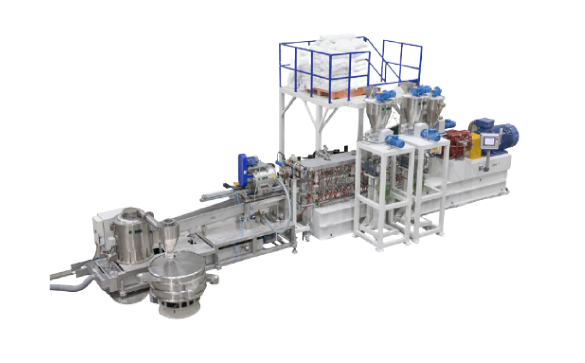

With Government announcing Digital India program to empower and bring together India’s social-commercial ecosystem, need for better communication infrastructure has seen a boost like never before. This machine contributes to the telecom infrastructure development. Producing Micro-duct at high line speed is a challenge in terms of maintaining good finish, wall thickness & ovality. Ovality is the most critical parameter which needs to be controlled for consequent operations of bunching & sheathing. This has been made possible by special design of vacuum tank with closed loop control of vacuum and capstun belt haul-off. With its unique micro-duct extrusion process that adheres to global standards, machine is capable of delivering consistent output of micro-duct without any change in design, configuration & characteristics of micro-duct.

Features

- High output rate to manufacture any type of micro-duct ranging from 5 mm to 16 mm OD.

- Ovality of the duct: 3 – 4 % of OD

- Winding capacity: up to 4 km - helps in longer production run while making bundled sheathing.

- Import substitute and export grade with much lower price than available options

- Unique design with less space requirement & lower production cost.

This extrusion line is available at a high speed of 50 MPM to manufacture Micro duct from 5 mm OD to 16 mm OD with Smooth as well as Ribbed ID. KET also offers Micro duct bundle sheathing Line from 2 ways up to 21 ways.

| Particulars | Specifications |

|---|---|

| Product Range | 5 mm to 16 mm OD |

| Operating Line Speed | max 50 MPM |

| Main Extruder | 45 mm, 30:1, B6 |

| Aux Extruder | 35 mm, 26:1 |

| Jokey Extruder | 25 mm, 24:1 |

| Screen Changer | Manual Lever Type VM50-MD |

| Die Head | CoexLabyfil 20/450L |

| Vacuum Tank | IVB 25-9M-SS |

| Cooling Bath +Drain Bath +Dryer Bath | 3 x 4 M + 2.5 M + 1.5 M |

| Air Dryer | Air Dryer V4 |

| Caterpillar Capstan | CC32 |

| Spool Winder | Microwind 800 |

| Automation Panel | NX 32 |