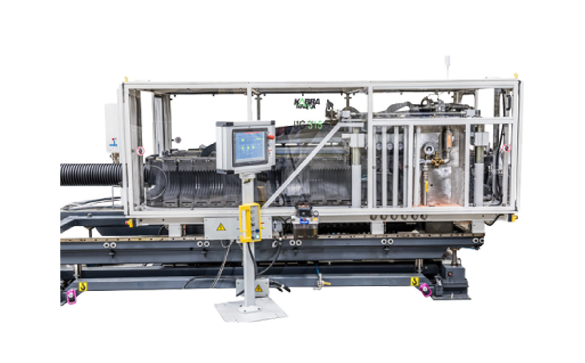

Microduct

With Government announcing Digital India program to empower and bring together India’s social-commercial ecosystem, need for better communication infrastructure has seen a boost like never before. This machine contributes to the telecom infrastructure development. Producing Micro-duct at high line speed is a challenge in terms of maintaining good finish, wall thickness & ovality. Ovality is the most critical parameter which needs to be controlled for consequent operations of bunching & sheathing. This has been made possible by special design of vacuum tank with closed loop control of vacuum and capstun belt haul-off. With its unique micro-duct extrusion process that adheres to global standards, machine is capable of delivering consistent output of micro-duct without any change in design, configuration & characteristics of micro-duct.

(1).webp)

.jpg)

.webp)

.jpg)

.jpg)